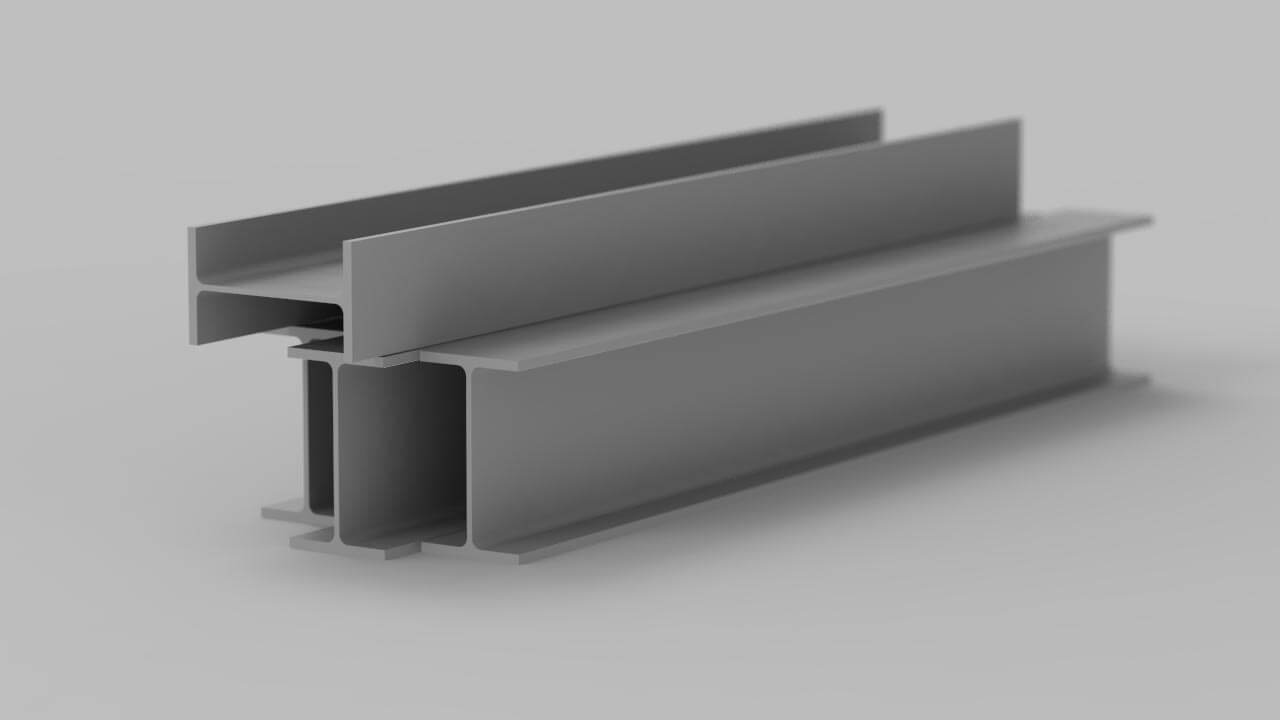

Steel Finishes

In construction and fabrication, steel stands out as a top material, with the chosen finish playing a key role. Each finish option—raw, primed, or galvanized—brings unique properties and applications, catering to diverse project requirements.