Universal Beams

- Made to measure UC beams

- Over 800 Trustpilot reviews

- Fast and competitive pricing

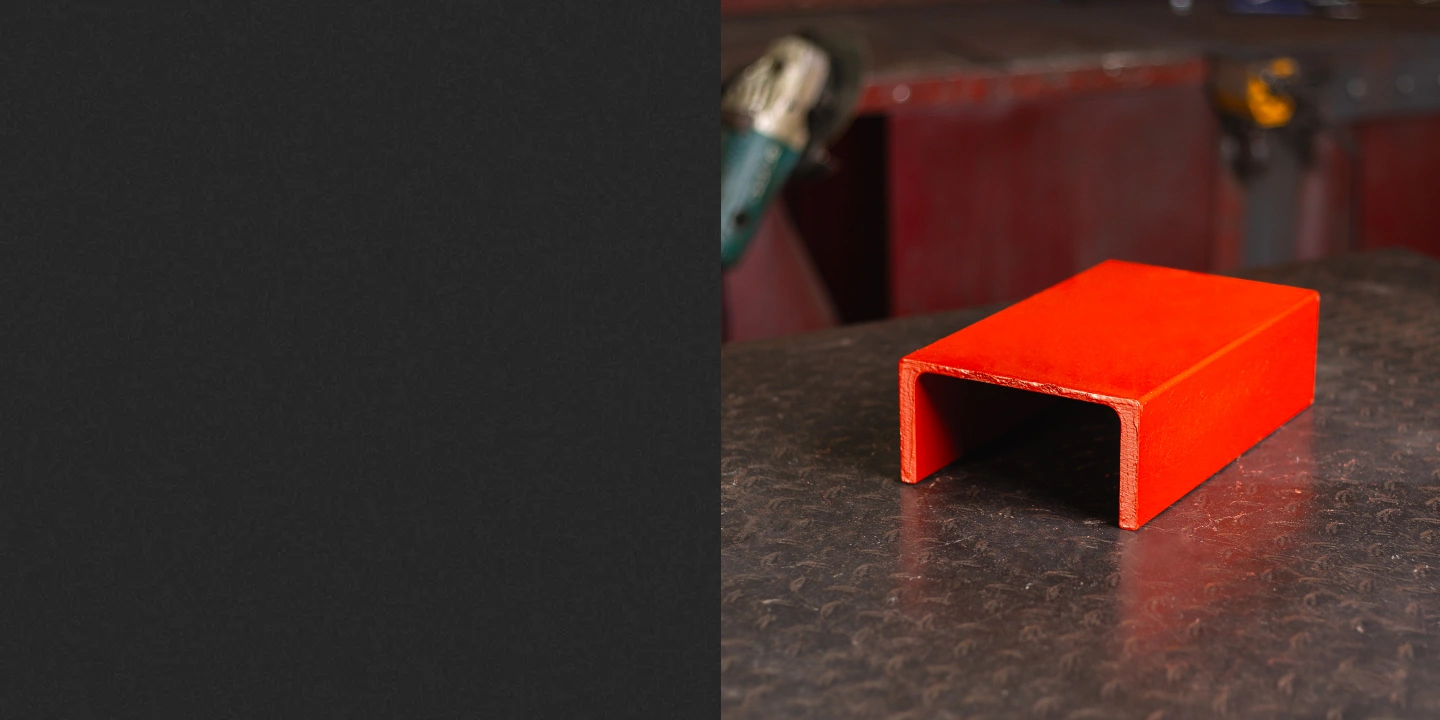

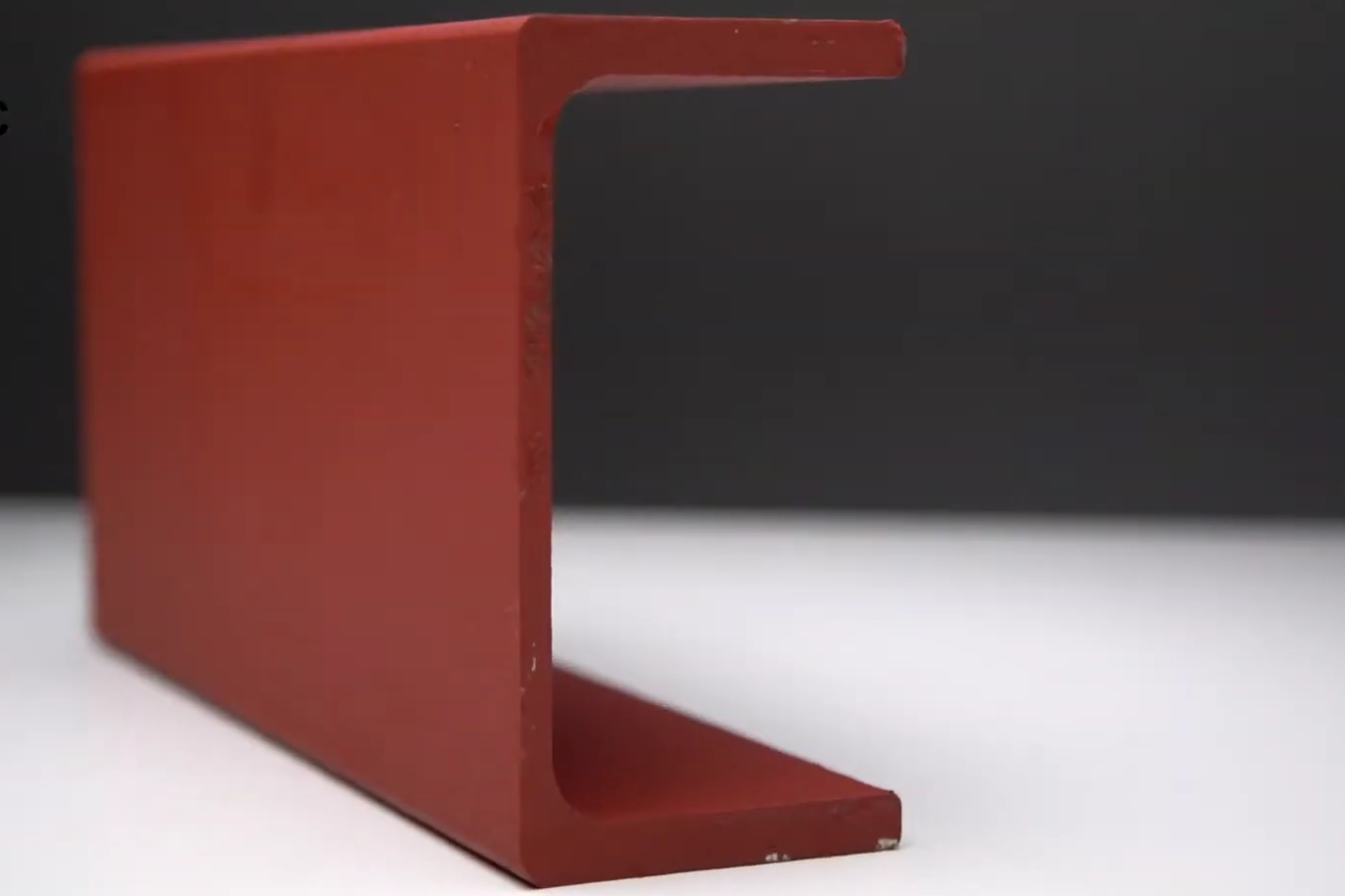

Parallel flange channel is normally called a channel or a “C-section”. They are described by their depth, width and weight per metre in kilograms, eg. 150 x 75 x 18 PFC.

The PFC is used for columns, lintels above doors or simply a steel beam supporting floor joists. When used for lintels, they have a bottom plate welded to it that takes the outer bricks or 2 channels are bolted back to back with 100 mm spacers to support both leafs of a cavity wall.

| Type | Weight [kg/m] | Height [mm] | Width [mm] | Web thickness [mm] | Flange thickness [mm] | |

|---|---|---|---|---|---|---|

| 01 | 100 x 50 x 10 PFC | 10.2 | 100 | 50 | 5.0 | 8.5 |

| 02 | 125 x 65 x 15 PFC | 14.8 | 125 | 65 | 5.5 | 9.5 |

| 03 | 150 x 75 x 18 PFC | 17.9 | 150 | 75 | 5.5 | 10.0 |

| 04 | 150 x 90 x 24 PFC | 23.9 | 150 | 90 | 6.5 | 12.0 |

| 05 | 180 x 75 x 20 PFC | 20.3 | 180 | 75 | 6.0 | 10.5 |

| 06 | 180 x 90 x 26 PFC | 26.1 | 180 | 90 | 6.5 | 12.5 |

| 07 | 200 x 75 x 23 PFC | 23.4 | 200 | 75 | 6.0 | 12.5 |

| 08 | 200 x 90 x 30 PFC | 29.7 | 200 | 90 | 7.0 | 14.0 |

| 09 | 230 x 75 x 26 PFC | 25.7 | 230 | 75 | 6.5 | 12.5 |

| 10 | 230 x 90 x 32 PFC | 32.2 | 230 | 90 | 7.5 | 14.0 |

| 11 | 260 x 75 x 28 PFC | 27.6 | 260 | 75 | 7.0 | 12.0 |

| 12 | 260 x 90 x 35 PFC | 34.8 | 260 | 90 | 8.0 | 14.0 |

| 13 | 300 x 90 x 41 PFC | 41.4 | 300 | 90 | 9.0 | 15.5 |

| 14 | 300 x 100 x 46 PFC | 45.5 | 300 | 100 | 9.0 | 16.5 |

| 15 | 380 x 100 x 54 PFC | 54.0 | 380 | 100 | 9.5 | 17.5 |

| 16 | 430 x 100 x 64 PFC | 64.4 | 430 | 100 | 11.0 | 19.0 |

PRODUCT CHARACTERISTICS:

Type, Weight, Height, Width, Web thickness, Flange thickness

Enjoy reliable and swift delivery straight to your site, ensuring you stay on schedule with minimum hassle. We call it “On-site, On-time, Every-time”.

Unparalleled Quality: Our steel beams are manufactured using the finest grade materials, ensuring utmost durability and strength.

Precise Engineering: Our advanced engineering capabilities guarantee precise, custom-fit solutions that meet the most demanding construction projects.

Wide Range of Options: Choose from our extensive selection of structural steel including universal columns, universal beams, PFC, RHS and SHS sections.

Competitive Prices: We always offer exceptional value with competitively priced steel beams, delivering superior quality without exceeding your budget.

Explore our some of our recent steel beam projects, showcasing the exceptional quality, precision, and versatility we bring to every build. From complex structures to simple configurations, you can count on the experienced Steelo team.

A PFC steel beam, or Parallel Flange Channel, is a structural component commonly used in construction and engineering projects. It features a ‘C’ shape with parallel flange edges, making it a popular choice for applications requiring strength and durability.

Known for its excellent load-bearing capabilities, the PFC beam is widely used in building frameworks and support structures. Its design allows for easy welding, bolting, and adaptability to various construction projects. PFC steel beams are available in different sizes and weights, ensuring flexibility for diverse project requirements.

For commercial and residential construction, universal beams are typically stronger than PFC steel beams. Universal beams feature a robust design with a vertical web and horizontal flanges, offering exceptional resistance to bending and deflection. This makes them ideal for load-bearing walls, floor systems, and other primary structural elements in larger-scale projects.

On the other hand, PFC beams, with their characteristic ‘C’ shape, are lighter and more suitable for secondary applications. They are often used in framing, lintels, or bracing where space or weight constraints are key considerations.

When making the choice between the two, it’s important to consider factors including load-bearing needs, weight considerations, and design constraints.

Joining PFC beams in construction projects typically involves welding, bolting, or a combination of both. The method chosen depends on the project’s design, structural requirements, and load conditions.

Welding: This is a common method for permanent connections, providing strong, seamless joints. It is ideal for applications requiring high strength and rigidity, such as frameworks or load-bearing components.

Bolting: Bolted connections are used for assemblies where disassembly or adjustment might be needed later. This method is particularly useful for prefabricated structures or where on-site flexibility is essential.

Fast Turnaround: With efficient production processes, we deliver steel quickly and reliably.

Combination: Some projects use both welding and bolting to achieve the required structural performance and ease of assembly.

It’s essential to ensure all joining methods comply with industry standards and are performed by qualified professionals to maintain structural integrity and safety.