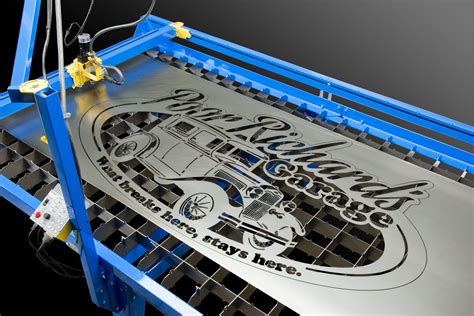

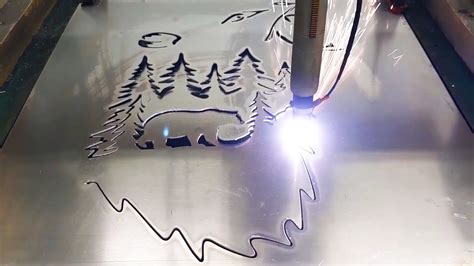

COMMON LASER CUT METALS

LASER cutters are suitable for a wide range of materials, including non-conductive ones, as they use a focused laser beam rather than electrical connection. Laser cutters typically cut up to 25mm thick plates, depending on factors like material and laser power. Non-conductive materials like wood, lead, tin, and manganese can be cut, unlike with plasma.

The following materials can be cut with a laser cutter:

- Mild steel

- Stainless steel

- Copper

- Brass

- Aluminum